How to measure a pneumatic wheel

In this guide we explain the key steps to measuring up your wheel filled with air (pneumatic).

Watch the process with Joel

Want a quick, easy demonstration of measuring a pneumatic wheel? Check out our video from resident wheel expert Joel Sankey:

Steps we cover

- Confirm the tyre is pneumatic or solid

- Check if you’ve got a steel rim or plastic rim

- Check tyre size printed on the tyre

- Measure your axle / bore diameter

- Get your hub width

- Measure your tread or profile width

- Get your wheel diameter

Step 1 - Confirm the tyre is pneumatic or solid

Pneumatic means filled with air, and has a tube valve poking out. The alternative is a solid wheel with no valve or air.

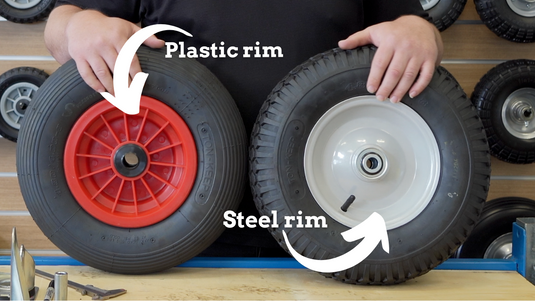

Step 2 - Check if you’ve got a steel rim or plastic rim

Pneumatic wheels come in steel rim or plastic rim - this should be pretty simple to ascertain just by looking at them.

Step 3 - Check numbers printed on the tyre - TOM - WHeel diameter should probably be here if thats ok? Then the rest are in order.

It’s a good idea to try and identify the tyre size numbers printed on the tyre. This will give you information about:

- Profile of the tyre

- The diameter

- The rim size

The rim size is especially important if you’re going to replace just a tyre (not the rim). Sometimes old tyres wear down and these reference numbers aren’t legible. But if they are, it can speed up the process a bit. Our team is well versed in what these mean so can assist you with finding the correct replacement using them.

Check for markings on your tyre ‘NHS’ - this stands for ‘Not for Highway Service’ - This will be found on equipment like lawn mowers, golf carts, some farm equipment and various other applications. Stuff that’d get you a ticket for using on public roads!

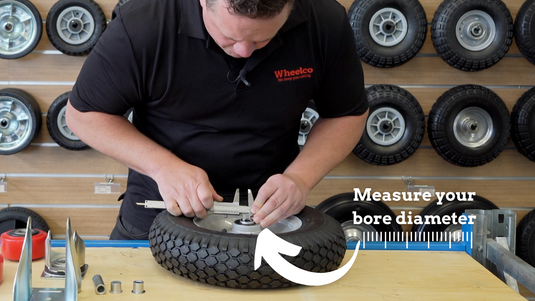

Step 4 - Measure your axle / bore diameter

Right now we’re into the measurement of our pneumatic wheel. The first thing to measure is the bore internal diameter.

The best way to do this is using some callipers if you’ve got them. Lay the pneumatic wheel flat on an even table and insert the callipers into the bore. This will help you get a good read on your diameter measurement.

If you don’t get the right measurement here - it’ll either not fit your application, or it’ll be loose on your axle which isn’t safe or very functional!

Step 5 - Get your hub width

As you look at your pneumatic wheel front on, the hub width is the measurement from one side of the hub to the other. This is important because if you get a wheel that’s too wide, your axle will be lost inside or the replacement wheel will not fit back into your housing.

On the flipside, if it’s too narrow a hub width, there’ll be a lot of ‘slop’ on your axle - not ideal!

So, to measure your hub width, use your callipers if you have them, simply run the measuring pin through one side of the hub and out through the other end, flush with the edge. This will give you a really precise measurement.

Not everyone has a set of callipers. Another way of doing this is by grabbing a pen, poking it through the hub and stopping flush with the other side. Simply pinch where the pen meets the edge and use a ruler or measuring tape to take the reading. Many of our customers use this technique successfully!

Step 6 - Measure your tread or profile width

Something to be aware of when replacing pneumatic wheels is to ensure your tread width will fit (and is suitable for) your application. Simply run your tape measure across the tread to get a reading.

Sometimes you’ll need a grippy tread for certain environments, or a smooth or ribbed tread for golf greens, smooth floors etc.

Step 7 - Get your wheel diameter

Now those tyre dimensions printed on the tyre are useful, but they aren’t always visible - especially for old, worn tyres.

So if that’s the case, it’s easily sorted - take your tape measure, lay your wheel flat and take the reading from end to end of the wheel, including the tyre.

If you just want to get the rim replaced or measured, take your reading from bead to bead.

Shop replacement pneumatic wheels with Wheelco

Get in touch

Stuck or just want some advice on the best way to replace your pneumatic wheel? Give us a ring on 0508 WHEELS (0508 943 357) or contact us via our website form.