All Pallet Jacks

Pallet Jacks and Trucks New Zealand

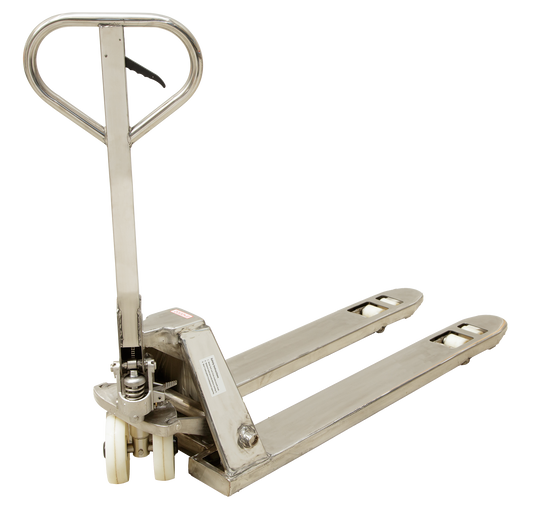

Moving pallets of stock or equipment around a commercial space brings with it a number of logistical and safety considerations. Pallets are typically heavy and therefore need to be carried in a way that protects the load and everyone around it. Wheelco supplies Kiwi businesses with pallet jacks that are commercial ready.

We’ve got your pallet jack needs covered - here’s why

Wheelco knows the business of carrying heavy loads in an industrial setting. We’ve built our reputation and business off the back of developing solutions that get the job done well. We supply only high grade equipment that’s proven in real world rigorous use. And with brands of pallet jacks like Jiffy and Prolift, we’re well-prepared to supply you with the tools you need for heavy pallet load carrying.

Our pallet jacks cover pretty much every pallet type you will find here, including the Chep pallet, Euro pallet, fruit bins, and non standard pallets, our 4 way pallet trucks/jacks will go in & lift the Chep pallets on any side, fully supporting the base to ensure the load is transported in a safe & efficient manner.

Our team tests every piece of equipment we stock, and our pallet trucks are used in our own warehouse everyday, put under heavy loads for extended periods of time. We stand behind the pallet trucks we supply to New Zealand.

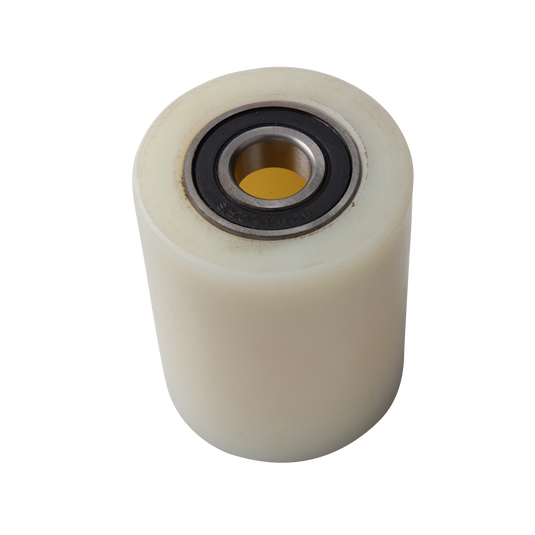

Another reason is that we carry a full backup of spare parts for our pallet jacks we supply, including wheels, rollers, handles, jacks/pumps, pins/axles, bearings, seals, push rods, clips, roll pins & plunger springs, ensuring that you have a full spare parts backup is crucial so customers can keep their operation running.

Who uses our Pallet Jacks?

Pallet trucks are the cornerstone of most landing bay/loading areas. Supermarkets and shopping malls require frequent offloading and movement of new stock arriving each day. Warehouses are also reliant upon pallet jacks for offloading and loading freight trucks, as well as stock/storage management. Our pallet trucks are also found in places like breweries, food processing, industrial applications and storage businesses.

Built for rigorous use - day in, day out

A pallet jack needs to do a number of things reliably; provide good heavy load movement and lift or drop the load safely. A good quality pallet truck will only require a few pumps to lift the load off the ground for movement - something our range offers. Given the components involved with a pallet truck and the duress they’ll be placed under, you need to choose a supplier that provides only long-lasting equipment. Failure of poor equipment creates hazards in the workplace - so choosing Wheelco for your pallet jacks helps to reduce these incidents with equipment that’s designed for prolonged heavy usage.

In our range you’ll find certain hallmarks of quality such as fully welded bodies from high grade steel, strengthened forks, rubber coated comfortable handles, and front rollers with multiple ball bearings to extend maintenance intervals.

Easy to operate

Operating a pallet truck needs to be done so with the right training and guidance, so ensure that you and your team are well trained on best operating practices. Our pallet equipment has been vetted to ensure it is easy to move around (both loaded and unloaded) and provides a smooth lift elevating/lowering action through the jack. Levers and handles are heavy duty, reassuring but approachable. No matter which of our range you choose, you can be assured that the equipment will never get in the way of your team’s ability to move around heavy loads in the workplace.

Designed for heavy loads

Our pallet jacks range from 1,000kg to 2,500kg, catering to a variety of load types. You’ll want to choose a pallet trolley that meets your maximum pallet weight not only with a stationery load, but during loading. It’s a good idea to leave some allowance between your load weight and the rated load of the truck.

A range of pallet shifting solutions

In our range you’ll find a number of different pallet jacks. Whether it’s hot dip galvanised corrosion resistance, a high-lift function, or even a built in digital scale, you’ll likely find a pallet jack that meets your needs. And if you have specific requirements outside of what we stock here on our website, get in touch with us and we can custom design a solution for you - we’ve built such solutions for applications like transporting helicopters from hangars, so we’re confident that no matter your needs we’ll be able to help.

Watch Our Latest Pallet Jack Product Overviews

Heading

Heading

Pallet types in New Zealand and matching jacks

| Pallet or bin | Typical size | Recommended jack | Notes |

|---|---|---|---|

| Chep pallet | 1200 x 1000 | Standard, 4 way entry | 4 way allows side entry in tight docks |

| Euro pallet | 1200 x 800 | Narrow or standard | Narrow width clears skids and racking beams |

| Fruit bin | Varies | 4 way entry | Supports entry any side in packhouses |

| Custom or non standard | Varies | Custom fork or high lift |

Frequently Asked Pallet Jack Questions

What capacity pallet jack do I need?

Pick a rating higher than your heaviest live load, not just static weight. Allow a margin for uneven floors, gradients and stop or start forces.

Can I use pallet jacks on ramps?

Short shallow ramps are fine with care. Keep loads low, face downhill when loaded and never exceed the maker guidance on gradient.

Do I need training to use a pallet jack?

Yes. Basic handling and safety training is required for safe use in the workplace. Keep records and refreshers.

Which jack is best for cool stores?

Galvanised jacks with poly rollers are common in chilled and wet areas due to corrosion resistance and smooth roll.

What is the difference between a pallet jack and a pallet truck?

They are the same thing. Terms vary by region. Both refer to a hand powered pallet mover with a hydraulic pump.

Glossary

Width over forks

The outside distance across the two forks. Needs to match the pallet opening.

Fork length

The length of each fork from the heel to the tip. Longer forks support long pallets and bins.

Entry roller

Small roller at the fork tip that helps the fork ride into the pallet opening.

Load centre

The distance from the fork heel to the centre of the load mass. Ratings assume a stated load centre.

4 way entry

Ability to enter a pallet from any side, helpful in tight docks and racking.