-

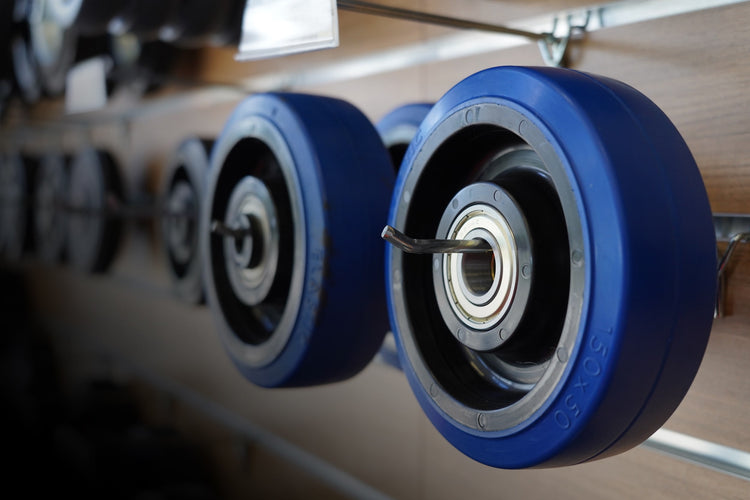

Wheels

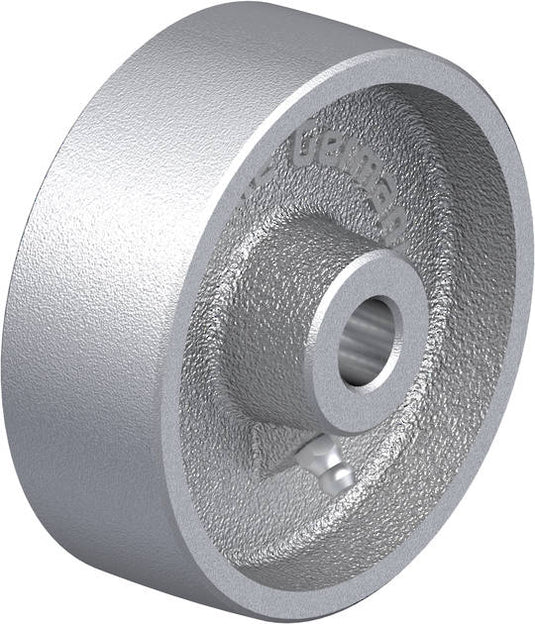

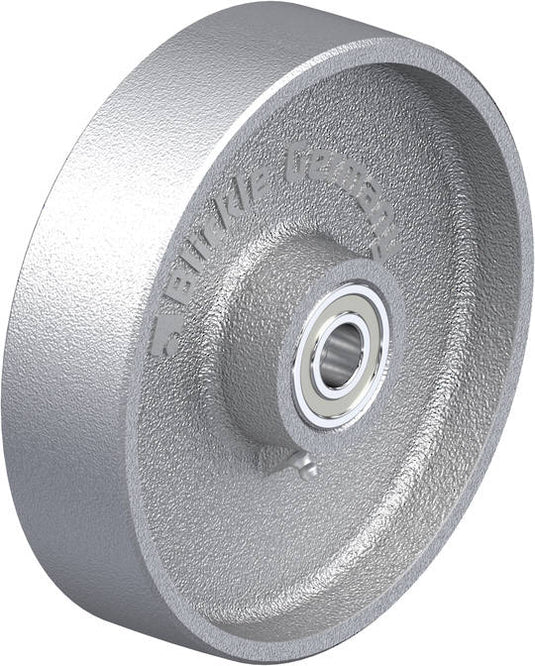

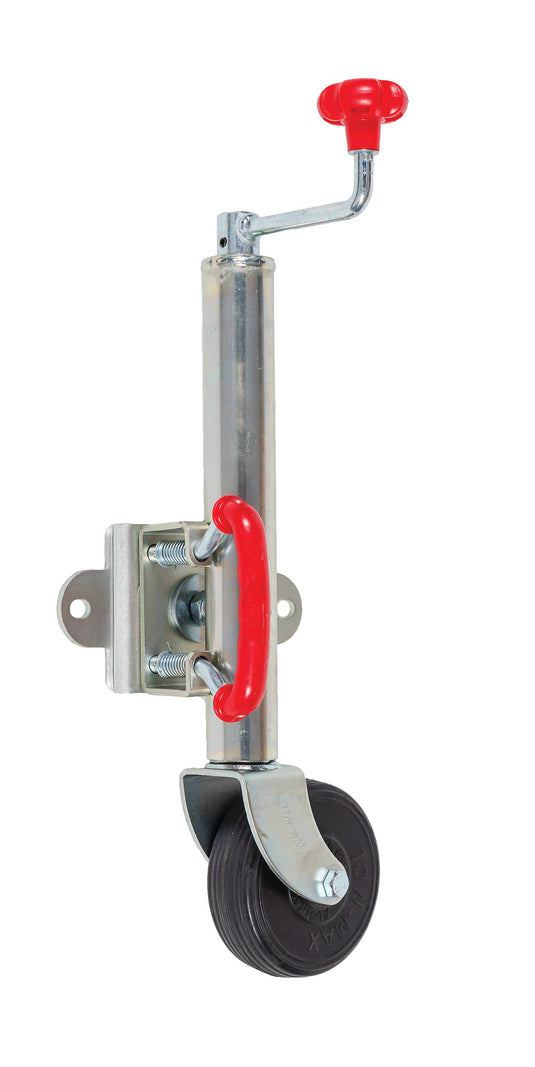

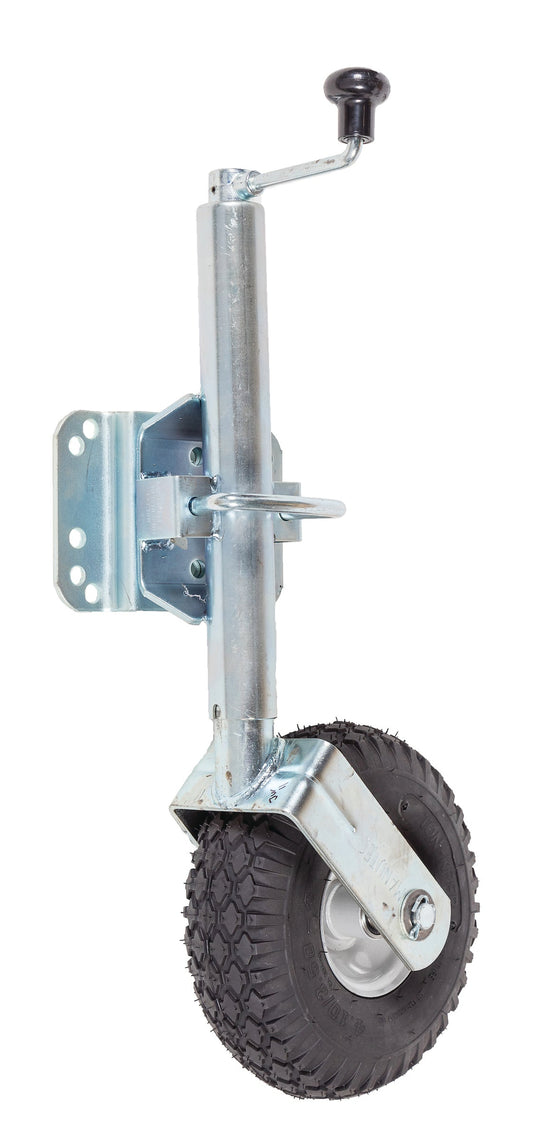

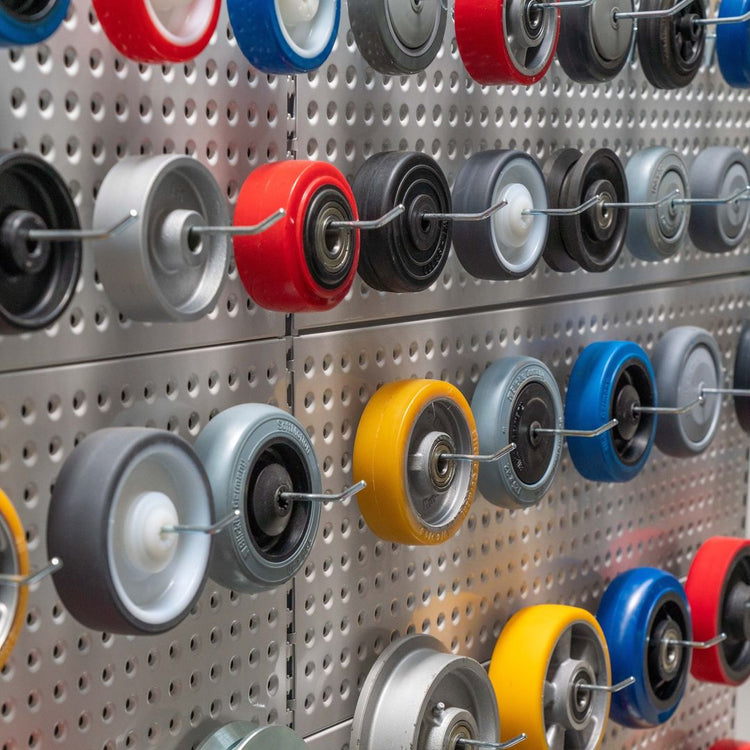

- Below you’ll find a large range of wheels for virtually any kind of application. We supply different sizes, tyre types, mounting configurations and materials. If it’s got a wheel, we likely have your needs sorted in our range. If not, we’ll work with you to source it quickly.

Types of Wheels

All Wheels

154 productsWhy you should choose us for your commercial wheel needs

Wheels. It’s at the core of what we’re all about. The sheer range of applications for industrial wheels is immense. We’ve been supplying Kiwi commercial operations with wheels of all kinds for over 25 years. Wheelco stocks a huge comprehensive range of wheels suitable to carry any load and roll over any terrain. You can easily find replacement wheels at Wheelco, the speciality wheel stockists in New Zealand.

Whether you are designing new projects or repairs and maintenance, we'll help you select the right wheel that's fit for purpose. And best of all we only pick the best quality products that last the distance and give you peace of mind! From 30mm nylon up to large pneumatic wheels and wheels carrying up to 10,000 KG we have you covered.

Where customers use our wheels

Wheelco is the provider to many different people and businesses for replacement and build of equipment. You’ll find our wheels on factory trolleys, lawn mowers, material handling, trailers, supermarket trolleys and pallet trucks, and large automotive or transport uses. Wheelco’s wheels are used to move aircraft from hangars, shift produce around factories, and help keep restaurants efficient.

You may come across our wheels in gates and sliding door applications, helping to keep a stable and smooth open and close.

Because of the variety of wheel types from cast iron to nylon to rubber, we supply to virtually anyone needing a wheel. There are few environments where we can not help out - wet, dry, hot, cold, corrosive, rough, heavy load, slippery. It’s no problem for Wheelco.

Industries that choose Wheelco

Much like our wheels can be used for almost anything, there’s a massive list of industries we work with. We help the likes of supermarkets, automotive garages, factories, chemicals, fuel. transport, restaurants and hospitality, aviation, rail, recycling and refuse, corporate office, construction, agribusiness, lawn care, freight, healthcare and many, many other industries.

Advice for buying industrial wheels online

If you’re looking to purchase your replacement or new wheel online, consider the following before you buy:

- Have you established the combined weight that you will need to move with the help of this wheel?

- Does the wheel you’re considered comfortably carry this load (combined by number of wheels the equipment will have)

- What sort of tyre is required for this application?

- Does the environment in which the equipment is being used have any temperature, chemical or other consideration to make?

- Have you picked the right wheel material to best accommodate these factors?

- How is the wheel mounted to your equipment? Consider the equipment’s own design - what sort plate will be needed to affix the wheel?

- Does the supplier you’re considering provide guidance around installation?

If you choose Wheelco, we’ll provide help with all of these questions and much more. Our team is made up of friendly, knowledgeable wheel experts who are dedicated to ensuring you get the best wheel for the job.

Bespoke builds available

While we’ve got plenty of experience in virtually every industry you could imagine, we also take pride in our ability to adapt to an unusual or custom wheel need and provide a great solution. If we can’t supply you ex-stock, we have access to thousands of non-standard options as well through our overseas supplier. The custom wheel projects we work on extend to building or assisting with the build of handling equipment to our customer’s specific requirements.

If you’ve got a piece of equipment, a space, or a particular function that needs a custom build, speak to our team for more information on how we can help get you rolling.

Excellent manufacturing standards and quality materials

All of our customers rely on Wheelco to get them wheels that function perfectly, and last the distance as well. Our quality standards with regards to the materials used, assembly quality control and attention to detail in design ensures you can install and use our wheels without hassle.

Getting help with wheel installation

If you do need advice around how best to install your new wheels, we’re able to provide pre and post purchase guidance. Through phone, email or even video call if needed, we can help determine the mounting style, type and wheel for your job. We may ask for some additional specs or measurements to help us give you the best advice. Depending on the wheel, we can supply files like CAD to aid compatibility check, mounting and preparation of load equipment.

Once you’ve ordered with Wheelco, our service doesn’t stop. We can help you reorder wheels in the future, or for a bigger order to a growing fleet of equipment (such as trolleys, chairs or office furniture).

-

We are not limited to off-the-shelf solutions. Wheelco can source specialist wheels for any situation.